By Vincent Wang, VP of Sales and Marketing, Asia

Light emitting diodes (LEDs) are a versatile, physically compact light source with a long operational life. They are also extremely efficient, far more so than incandescent bulbs, with high-brightness LEDs (HB-LEDs) now available that exceed 200 lumens per watt (lm/W). This lends itself to be an ideal choice for illuminating interior and exterior automotive applications.

HB-LEDs, deployed in an array configuration within a vehicle’s headlight assembly can produce high-intensity light beams that, in some modern vehicles, will also angle the beam in relation to the steering wheel position – so-called beam steering. HB-LEDs can also be used within the cabin to illuminate light pipes to create engaging lighting effects around the dashboard, door paneling, console displays, and other structures. The impact of light as a vehicle interior design element has been discussed for a number of years, including in an article in the German publication all-electronics.de1, that makes this key point:

“The interior is becoming more important for both drivers and car manufacturers. In addition to dynamic lighting, LEDs also open up new design possibilities and they can draw the driver’s attention to certain points. In order to fulfill these functions, LED manufacturers are constantly improving their products. Improved color stability, miniaturization, integrated drivers are just a part of the possibilities that LEDs offer today.”

The role played by light is changing, from simple (white light) illumination and signaling tasks to enhancing the user experience (UX), in terms of comfort and safety, with multicolored lights. The ISELED Alliance, has this to say:

“With the trend to more driver assistance systems on the way to the self-driving car, light in the vehicle is also increasingly taking on functional tasks, for example to warn the driver of critical traffic situations.”

While LEDs have many uses, are efficient and within the cabin, and thanks to light pipes, can be used to illuminate multiple surfaces, driving the LEDs for a high quality and consistent experience is quite challenging.

In the majority of automotive applications, LEDs – whether high brightness or not – require a drive current from a voltage source that is higher than the operating voltage of the device; and readers who have used DC voltage regulators will be familiar with the problem we are about to discuss.

The potential difference between the source voltage and the load voltage multiplied by the current flowing through the load is wasted power (largely in the form of heat). In automotive and other applications, LEDs are driven by either a linear LED driver or a switch-mode power supply. If we consider the former used in a 12V system to drive a 3V LED that draws 20mA, then 180mW needs to be dissipated as heat.

This may be acceptable for a single, standard LED, but an HB-LED might require 200mA per RGB channel; and 9V x 600mA equates to 5.4W of heat.

On the other hand, switch-mode power supplies are more efficient because they include a DC-DC buck converter. It is a relatively simple circuit with few parts: a solid-state switch (a MOSFET, BJT, or IGBT for example), a freewheeling diode, a resistor, an inductor, and a capacitor (these last three acting as an LCR low-pass filter to reduce ripple voltage on the output). The solid-state switch is controlled via pulse-width modulation (PWM) at a constant frequency. Depending upon the converter, this frequency will be between 100kHz and a few MHz.

A buck converter has the ability to decrease voltage while increasing current – in much the same way an AC transformer does – and device efficiency is usually upwards of 85%. In this way, a lower voltage (say 4.5V) can be made available for the LED and its driver circuit. This approach is far more efficient for HB-LEDs.

However, as mentioned, a step-down buck converter is switching all the time. If the converter or any other part of the light circuit is producing electromagnetic interference (EMI), neighboring electronics might be impacted by radiated or conducted emissions. Similarly, it is important that the light circuit is not susceptible to EMI as that could result in flashing or reduced or intermittent brightness or color shifts, all of which could be a distraction to the driver.

Thermal and EMC management are therefore key considerations when designing the lighting circuit’s PCB and wiring – and these are challenges that the automotive sector is facing more and more, considering the growing deployment of semiconductor-enabled electronics in vehicles, further driven by automotive electrification, automation, and in-cabin user experience.

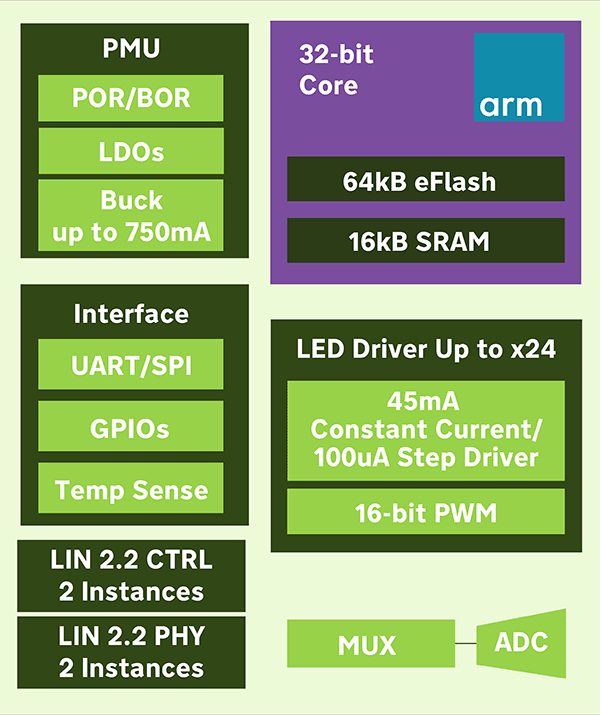

Also, and as the first quote mentioned, integrated drivers are part of the automotive lighting story. This brings us to devices such as indie’s iND83211 (figure 1). Requiring minimal external components and designed to drive LEDs efficiently and accurately at their maximum luminous output without exceeding safe operating conditions, the iND83211 features an integrated 32-bit Arm® Cortex® M0 processor, with 64kB of Flash and 16kB of SRAM. Unique to this IC is a built-in power management unit that implements a step-down buck converter and two on-chip voltage regulators. This is the key to creating a small form factor, high-power, and flexible power management system capable of driving 24 LEDs or 8 x RGB channels. The device can also be used to drive fewer LEDs at higher currents to create LED ‘light pipes’ that transport light from an LED source to where it is needed – a feature that is becoming increasingly popular in newer vehicles. And because the IC can withstand a 40V load dump from the car battery, it can be connected directly to the automotive supply, further minimizing the need for additional components.

Figure 1: Block diagram of the iND83211 System-on-Chip

If you enjoyed this blog post and would like to learn more about driving LEDs, check out our whitepaper ‘Redefining the Future of In-Cabin Lighting’. In it we take a deeper dive into the requirements for modern vehicle LED lighting, including a more detailed comparison of using linear LED drivers and buck converters.