Applications

- Interior/Exterior lighting with narrow lossy light guides

- Fuel gauge indicators

- Overhead light/reading map

- Taillight and turning indicators

- Charging ports

- Grill and logo lighting

- External decorating lamps

Features

- 24x LED drivers

- 32-bit Arm® Cortex® M0 Processor

- 64kB Flash / 16kB SRAM

- Integrated Buck converter and regulators

- 24x 45mA configurable LED drivers with 100uA steps

- 24x 16-bit PWM controllers

- 9 GPIOs

- 10-bit ADC

- UART Interface

- SPI Interface

- Dual LIN 2.2 J2602 interface

- Optimized for Automotive applications

| Device Name | Platform | Temp Range | Package | Pins |

|---|---|---|---|---|

| iND83211 | Automotive | -40C to +125C | 6×6 mm QFN | 48 Pins @ 0.4 mm Pitch |

iND83211 is an automotive-grade LED lighting IC driver with an integrated 32-bit Arm® Cortex® M0 processor, 64kB of Flash and 16kB of SRAM, creating a single solution for interior lighting systems. The IC includes a flexible power management system, up to 24x 5V programmable current, open-drain IOs with 16-bit pulse width modulation (PWM), plus monitoring features and automotive LIN interfaces. The device can be connected directly to the automotive supply and can withstand a 40V load dump from the car battery. The integrated power management unit implements a step-down buck converter and two on-chip voltage regulators with external capacitors.

Driving high-power LEDs using iND83211

The integrated step-down buck converter makes the iND83211 an ideal choice for driving high-power LEDs. The device is capable of delivering the maximum constant current while maintaining low-power dissipation to minimize the LED’s junction temperature associated with decreased operating life and performance and help to meet the stringent thermal requirements of these types of applications.

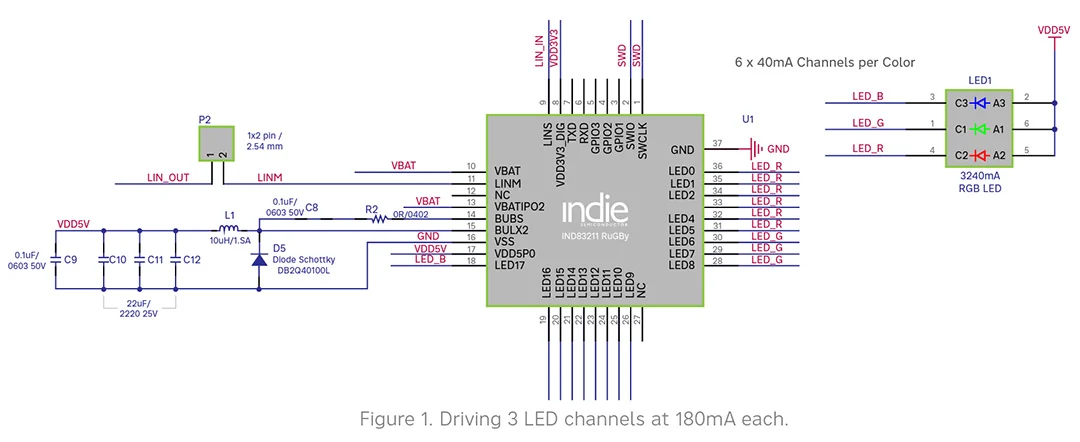

The buck converter delivers up to 750mA supporting high-current LEDs which require more than 200mA per RGB channel. The buck converter has a 5V nominal output that can be adjusted down to 3.8V while keeping the current constant. In addition, any of the 24 channels can be connected in parallel to increase the current-sinking capabilities. The current for each channel can also be configured in the firmware to optimally distribute the loads.

Color and intensity stability

To maintain stable color and intensity when there are temperature fluctuations, the iND83211 hardware includes a proprietary LED PN voltage detection circuit to accurately measure the LED temperature. Once the junction temperature is measured, a color correction factor is calculated using the on-chip 32-bit Arm® Cortex® M0 processor and applied to each individual channel RGB using the 16-bit PWM and 100uA current stepping hardware. In addition, an integrated temperature sensor sets a specified limit to ensure the LEDs and supporting components do not exceed their operational limits and risk overheating.

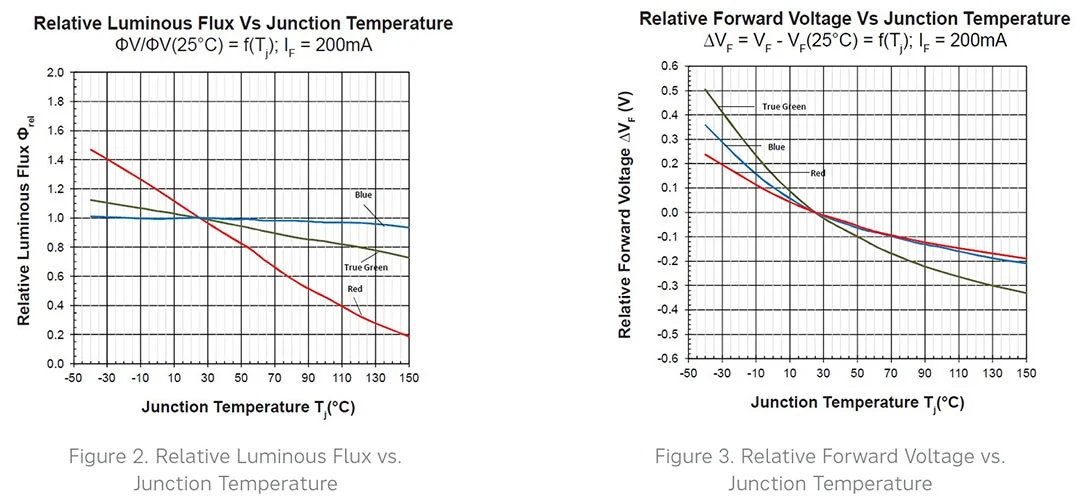

The luminous flux for each color varies differently as LED junction temperature changes. As shown in Figure 2, there is only a slight variation for blue but red has significant luminance loss as temperature increases. iND83211 uses the LED voltage across each LED PN to determine the LED junction temperature. Figure 3 shows the relationship of the forward LED PN voltage with LED junction temperature.

Two LIN transceivers create a fixed connection using node configuration and identification service or auto addressing with slave node position detection. This interface is used to send or receive commands, diagnostic, and status information. With the embedded core, the iND83211 can adjust the color of the LEDs using only the received color coordinates; all required configuration hardware parameters are calculated on the fly.

The iND83211 can efficiently and accurately drive LEDs at their maximum luminous output without exceeding safe operating conditions, requires minimal external components and is housed in a compact 6×6 mm package. The device’s hardware features, combined with indie’s extensive software library, makes the iND83211 an excellent system solution for high-power LED applications.